| Nie | Nazwa urządzenia | Jednostka | Ilość | Główne funkcje |

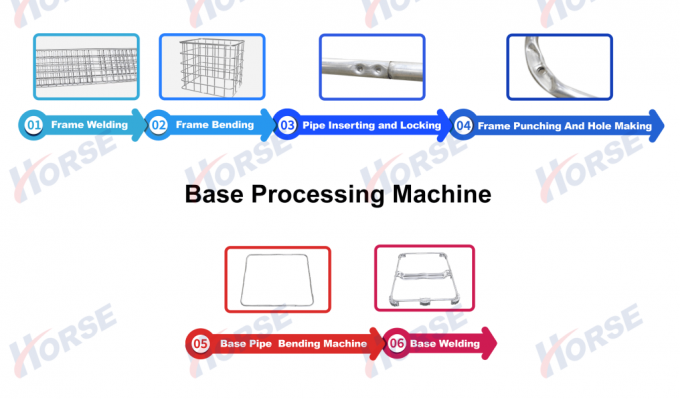

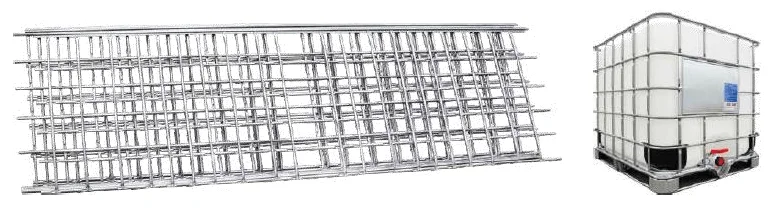

| 1 | Maszyna spawalnicza z poręczami sieciowymi | Jednostka | 1 | Zgrzewanie wielopunktowe z siatką |

| 2 | Maszyna do automatycznego karmienia siatką | Zestaw | 1 | Automatyczne ładowanie długich i krótkich rur |

| 3 | Manipulator przyjmowania materiału sieciowego | Jednostka | 1 | Rozładowanie siatki (uszywanie) |

| 4 | Maszyny do gięcia czteroma osiami | Zestaw | 1 | Zgięcie i formowanie oczek z głowicą skurczeniową |

| 5 | Maszyna zamykająca | Zestaw | 1 | Zgięcie i zablokowanie siatki |

| 6 | Maszyny do drukowania płaskich | Zestaw | 1 | Perforacja i cięcie rury dolnej pod ramą |

| 7 | Manipulator ramy | Zestaw | 1 | Trzy manipulatory poruszają się w górę i w dół, aby złapać ramę |

| 8 | Maszyna do spawania stóp ze stali | Zestaw | 1 | Słucie stóp stalowych ramy dolnej |

| 9 | Manipulator do odbierania materiału maszyny spawalniczej ze stali | Zestaw | 1 | Wyjmowanie, przenoszenie i układanie ramy dolnej po spawaniu |

| 10 | Automatyczna maszyna szczelna | Zestaw | 1 | Badanie szczelności podszewki |

| 11 | Automatyczne podwójne gięcie rury dolnej | Zestaw | 1 | Zmniejszanie, wytłaczanie i gięcie rury dolnej |

| 12 | Placówka badawcza drgań | Zestaw | 1 | Badanie trwałości i ochrony beczek IBC |

Zostaw wiadomość

Oddzwonimy wkrótce!

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Proszę sprawdzić email!

Proszę sprawdzić email!

Zatwierdź

Więcej informacji ułatwia lepszą komunikację.

Pan.

- Pan.

- Pani.

dobrze

Przesłano pomyślnie!

Oddzwonimy wkrótce!

dobrze

Zostaw wiadomość

Oddzwonimy wkrótce!

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Proszę sprawdzić email!

Proszę sprawdzić email!

Zatwierdź